What is the ‘Human Factors’ process and why is it so important?

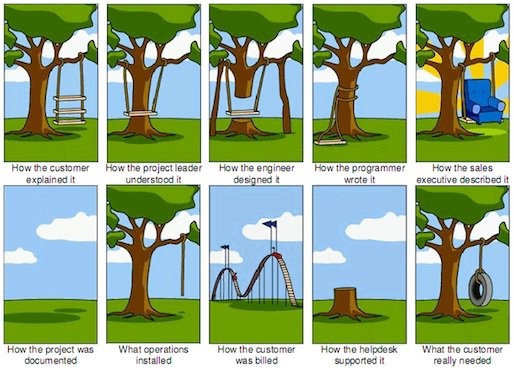

Sometimes a picture is worth a thousand words:

[Source: https://www.tamingdata.com/2010/07/08/the-project-management-tree-swing-cartoon-past-and-present/]

Formal human factors evaluation wasn’t a “thing” prior to 2000. Product use was part of the Risk Analysis which is part of the formal Design Controls associated with medical device design. The risk assessment included Use risk, of which human factors is a part. However it was fairly open loop. That changed with the publication of FDA Guidance in 2000, and similar changes in the European Med Dev, specific to Device, which codified expectations regarding the expectations for human factors assessments in regulatory submissions. So, at the end of the day, it’s a rule and you gotta do it.

Engineers tend to think their ideas will work. After all, they are human and if they can use a tool, anyone should be able to. That is a pre-supposition among many designers, medical product or otherwise. Most organizations I’ve worked for have incorporated some form of usability assessment in both design and risk management, but in an ad hoc manner.

Like so many things, regulations codify perceived “best practices”. Organizations see that the early inclusion of human factors assessment improved the products that came out, and decided that formalizing the process of human factors assessment and feedback into the design loop was a good thing which improved products. There are still a lot of companies out there (medical device) who don’t yet understand the importance of human factors, till it bites them in their submission.

Companies can pay lip service to the regulations (which is a waste) or they can embrace the best practices to improve their products and their product development process.

How has this process evolved within medical device, drug and combination products?

Even though it’s been over a decade since human factors was recognized as important, many medical device companies are still ignorant to the rules or are just getting exposed to them now.

Drugs were formally dragged into the Human Factors world by two guidances. The FDA defined the expectations around combination products. And about 5 years ago, FDA formally recognized things like prefilled syringes and cartridges as combination products.

Since that time, both companies and regulatory agencies have begun to recognize the value of HF assessments throughout the medical products industry.

What is the responsibility of the pharmaceutical industry in protecting patients against human error?

Ethically, it’s the right thing to do. Practically, now it’s the law to evaluate and mitigate the risk of human error associated with product design. And human error is a significant contributor to morbidity and mortality.

The business case is also pretty straight forward. If your product is hard to use and the competition is easier, your product won’t last long. If your product requires significant training resources and your competition doesn’t, you’re at a significant cost disadvantage. And if, god forbid, your product kills people, on occasion, your company isn’t likely to survive either. Wouldn’t you want to prevent these situations?

Interested in learning more about Human Factors in drug delivery and med device? Register for MassBio's forum: https://www.massbio.org/events/factoring-in-human-factors-what-you-don-t-know-can-hurt-you-2257